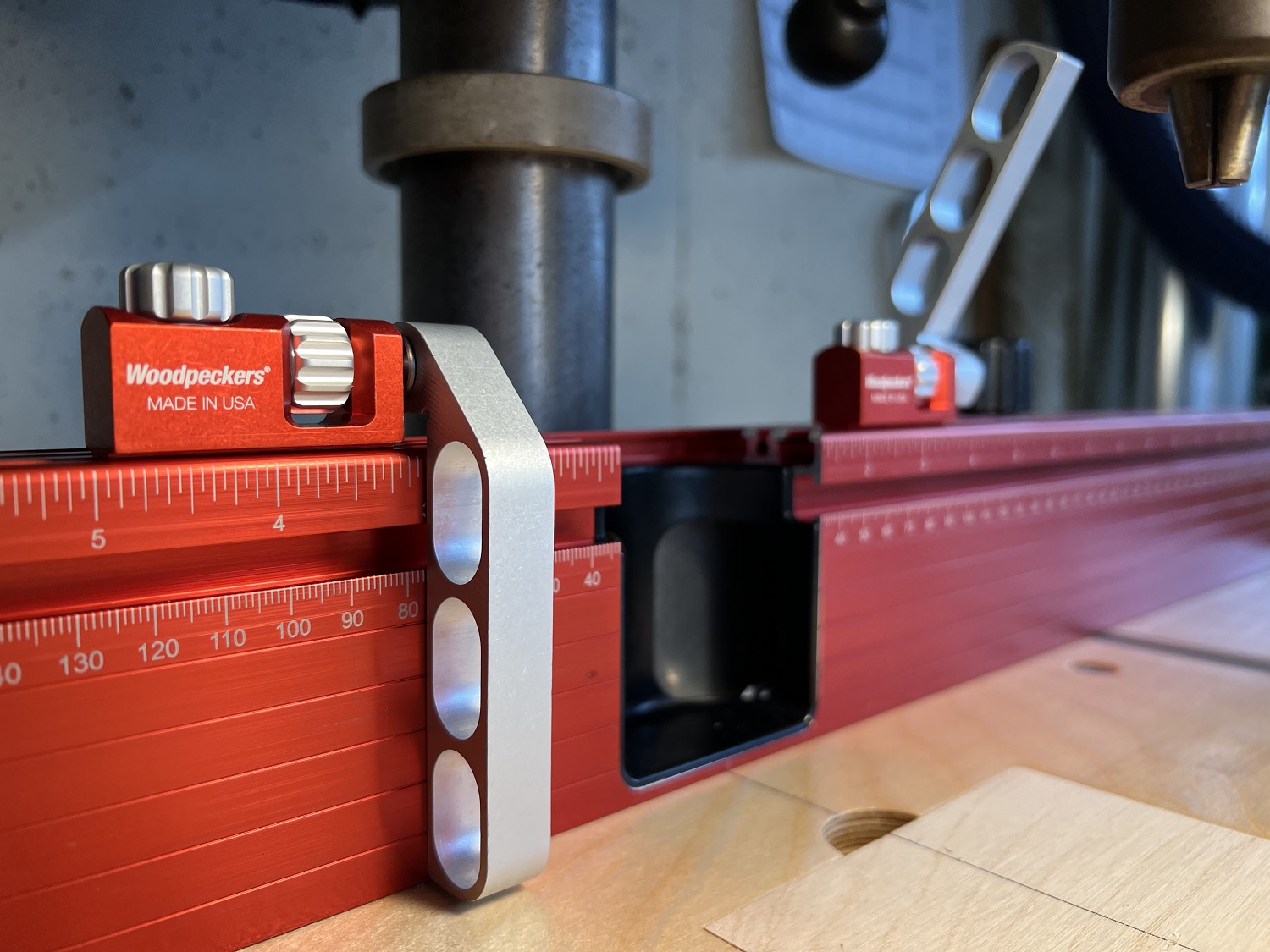

The Woodpeckers DP-Pro fence incorporates an innovative dust collection design that works well and adds no thickness to the fence at the column, minimizing the swing capacity taken up by the fence. The flip stops with micro adjustment and clearly legible scales are a pleasure to use and to behold. And, not surprisingly, the fit, finish and quality of the fence are all executed to the high standards we have come to expect from Woodpeckers. In my opinion, it is the best commercial drill press fence currently available. Though it’s not perfect, it’s pretty close.

Why Buy a Fence When You Can Make One?

My shop-built drill press table and fence has served me well for many years. This drill press has been in my shop for 19 years and I built this table for it within the first week of ownership.

However, there are a number of issues with it that needed to be addressed. The relief in the top of the fence is not deep enough and I have run the chuck into it a number of times making holes close to the fence.

Another vexing issue is that the pinion shaft handles hit the fence clamp knobs if the table is too high. The right knob is about 1/2″ too close to the pinion shaft—d’oh!

The third issue is the size of the fence and table. Although it’s not a big deal, I have often wished the fence were longer so that my stop block would have more travel. I have also wished that the table was wider when I’m dealing with long stock.

Finally, dust collection on this set up consists of a stay-put hose that either has to be positioned for the cut, which is a hassle and often in the way, or just used afterwards to clean up the mess. It would be great if dust collection were integrated in the fence right at the bit without interfering with the column and without taking up precious swing capacity. Yeah, that would be awesome.

My plan was to build a new table and fence that would—at a minimum—solve the first three problems. But as I was searching the net for ideas on drill press dust collection, I ran across the Woodpeckers DP-Pro fence and table system, and I started really considering buying a fence rather than building one.

Dust Collection Awesomeness, Slick Design, and Functionality

This fence has the best dust collection design I have seen. It is completely clear of the column and integrated into the fence, which is relieved at the chuck to provide more than adequate clearance. It works great for holes close to the fence and the stay-put hose easily plugs into, and out of, the fence to clean up stray chips for holes farther away.

This design is superior to the other commercial (and for that matter, shop-made) fence designs that I have seen with dust collection ports behind the chuck because they take up considerably more space in front of the column. Swing capacity is a precious commodity on a drill press.

I also considered other designs that are independent of the fence. One such approach is a contraption that surrounds the quill, chuck, and/or bit. This would undoubtedly drive me crazy in actual use. Another solution is slots in the table with a dust box underneath. This might work okay, but would be blocked by the work most of the time and would often be less effective at active collection while the drilling is being done. In addition, recognizing that dust collection on a drill press will never be perfect, I like having the hose easily accessible and within reach to clean up anything that doesn’t get sucked into the fence.

The slots for the hold-down bolts are on 14″ centers and they are 2″ long. This gave me plenty of room to mount the t-track in a position that would allow the locking knobs to clear the pinion shaft handles, so this fence solves that problem as well.

The fence is 3″ high, which is adequate to support work vertically, but not so high as to interfere with the pinion shaft handles when you raise the table high enough to use a small bit. Perfect.

And let’s be honest here—the form factor and flip stops are really slick:

Finally, unlike split fence designs, the DP-Pro has a centerline conveniently located at the base to keep it on the centerline of the table. This makes it easy to keep the scales—which run from the center of the chuck—accurate and useful. The DP-Pro also also improves the split fence design by keeping a registration surface available at the chuck for small work pieces, while leaving the dust port wide open.

DP-Pro Fence and Table Package?

Woodpeckers offers a beautiful and functional DP-Pro table that can be packaged together with the fence, flip stops, and knuckle clamps. It’s very nice, but I decided to just get the 36″ fence alone for several reasons.

First, I already had a means of attaching the table to my drill press and it takes up less space than the drawer unit that comes with the Woodpeckers table.

Second, I don’t need the drawer under the table because I already have drawers in the cabinet I built for the drill press. The drawer would be great if I didn’t have one though, and it also serves to elevate the table so that it won’t interfere with the crank that raises and lowers the table. This is smart, but I made a crank extension that solves this problem without taking up any vertical table capacity.

Third, the table doesn’t offer any special functionality that I need. I don’t need the depth scales in the table because, unlike a table saw fence, I would not trust a drill press fence to set this dimension. Since I’d have to confirm depth on my layout line anyway, the scales just don’t add any value. Extendable wings are nice, but I don’t need to conserve space at the drill press.

Finally, the Woodpeckers table is pretty expensive. The 36” fence packaged with the matching table is priced at a whopping $550. Since I can easily build a table with all the functionality I want for a fraction of the cost, the value proposition just isn’t there for me given my particular needs.

By contrast, the value proposition on the fence makes sense to me. Although I could probably find a suitable piece of extruded aluminum, fittings, and scales to make one, I don’t have any experience milling aluminum extrusions, and the parts I would need certainly didn’t jump out at me after a few quick searches. Given the difficulty of sourcing the parts, milling out the extruded aluminum, incorporating scales, etc., I don’t think the savings would outweigh the hassle factor. And it probably wouldn’t turn out quite as well–or as nice.

I mean, come on…it’s a beautiful bit of kit.

A Word About the Flip Stops

Unfortunately, every flip stop I have seen has some slop in it, and these are no exception. To the left of the quill, the stops are virtually slop free because gravity is already taking up the slop in the same direction that the workpiece will push them. But on the right side of the quill, you have the opposite situation and you get about 1/32″ of slop unless the micro adjusters are tightened down.

I know that a slop-free flip stop could be produced. It’s not rocket science: just make the shoulder of the micro adjuster bolt and housing longer, and maybe tighten up the tolerance a bit. Anyway, no one seems to want to build a flip stop this way, including Woodpeckers, which is admittedly a small disappointment.

Fortunately, as long as you are aware of it, there is an easy way to make this slop irrelevant. Simply push the workpiece into the locked down stop as you micro-adjust to your layout line. Alternatively, if you are looking for a hole that is located using the scale on the fence, simply tighten the micro adjuster down before you set the stop to the fence. The micro adjusters are not needed here, as it is easy to align the stops within the resolution of the scales. If you need it more precise than 1/16″ or 1mm, then you really should be setting it up to your layout lines anyway. We can’t lose sight of the fact that this is a drill press fence—not a table saw fence. I usually set up to layout lines on my drill press, and use the fence and stops for batching out repeat cuts from there.

Almost Perfect, but not Quite

My only real complaint about the fence is that it takes up 2.25″ in front of the column (4.5″ of swing). That’s better than other commercial units, but it’s still significant on a 12″ drill press. My shop-built fence took up 1.75″ and I was hoping to improve on that with the new table. Woodpeckers should relieve the .75″ flange behind the fence to clear the column, which would produce an extra 1.5″ of swing and improve on my shop-made fence’s clearance. I honestly do not understand this oversight because the thing that makes this fence stand out is the sleek design made possible by using the hollow fence extrusion as the dust port duct.

I may cut a relief in the flange myself, but I’m reluctant. Maybe one day when I really need that extra 3/4″, if that day ever comes.

Conclusion: 4 out of 5 Stars — Recommended

Overall, I would give it 4 of 5 stars. I would buy it again after getting to know it. Here’s the new table with the fence installed.