Three of six beautiful mahogany ladderback dining table chairs, hand made in England in 1930, were damaged in a move and required restoration. The worst of the three had two of the four stretchers completely missing, and loose mortise and tenon joints all around the apron. It required a complete rebuild, though the ladderback could be saved. The upholstery on all six chairs is old and stained and will be replaced as part of the restoration.

Repairing some minor break-out from disassembly.

The existing mortises are cleaned up with a chisel. Some had broken tenons embedded in them, which were drilled out and removed with a chisel.

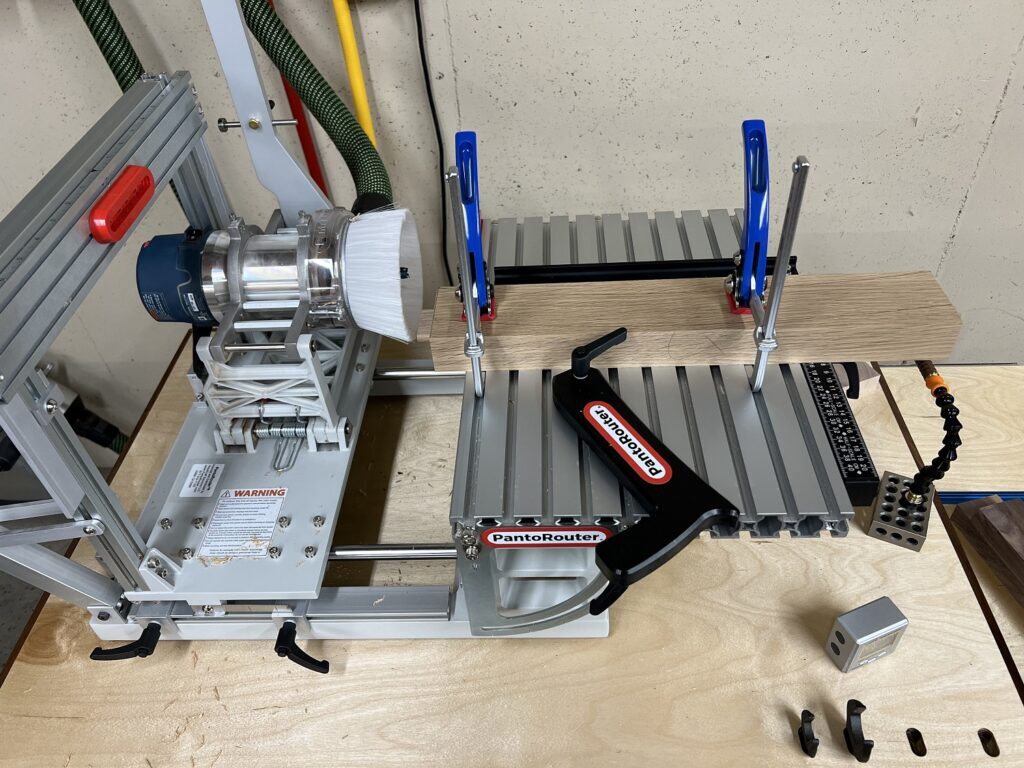

The new front apron is traced out on some 8/4 white oak, cut on the table saw, jointed and planed, and then taken to the PantoRouter to cut the tenons.

Then over to the band saw and sanders to shape the curve of the front apron.

A bit of sanding completes the new front apron.

Next to make the replacement side aprons, which have angled tenons.

Upon trial fitting, I realized for the first time that the original maker (in 1930) laid out the mortises in the ladder backs by hand, and they were not precisely square with the stock. Unfortunately, the new tenons are, so the original mortises were plugged and filled with epoxy, then recut.

Now it’s a nice fit.

Now to make the new mahogany stretchers.

The stretchers are ripped from a piece of mahogany, jointed and planed to final dimension. Then the joinery is laid out based on one of the old damaged stretchers.

I couldn’t get a hand saw on this side of the tenon because the entry point was right at the corner of the end, so a chisel was used instead.

Now to make the cross brace.

First the mortises are cut in the stretchers to receive the cross brace.

Next, the tenons are cut.

Dry fit looks good.

Now to round over the top edges to match the original stretchers and cross brace. A 1/8″ roundover bit and a concave spokeshave were used to match the original profile.

Now to attempt to match the finish. The chairs have a penetrating oil finish, presumably with a pigment because they are darker and more brown than natural mahogany. Varathane Red Mahogany was selected as the closest match.

After two applications of the stain, the color match looks pretty good.

Now on to the next chair. The left side of the chair is missing the stretcher and the cross brace, and the joinery is loose on the left and front apron. The right apron and stretcher are salvageable.

After removal of the upholstery and disassembly, the tenons from the broken stretchers must be extracted from their mortises.

The mortises and existing tenons are cleaned up and a new stretcher is made.

The apron tenons that had broken loose were thickened with a thin piece of mahogany, glued to the tenon, and then sanded down to match the existing mortise.

With the replacement structural members completed, the worst of the three damaged chairs is glued up and reassembled. The restoration of this chair is complete and it is virtually a brand new chair: the aprons, stretchers, and cross brace were all replaced with new parts made by hand in the same way as the original maker. The mortises on the ladderbacks were plugged and recut. All that remains is upholstery.

The rest of the set of chairs are stripped of upholstery and recovered with fabric from Ethan Allen. This will be my first attempt at upholstery, and admittedly, it did not go very well. But the chairs are my own, so I may Perhaps I’ll take a second stab at it at some point.