Every wood shop needs a sandpaper station. This is the build for mine.

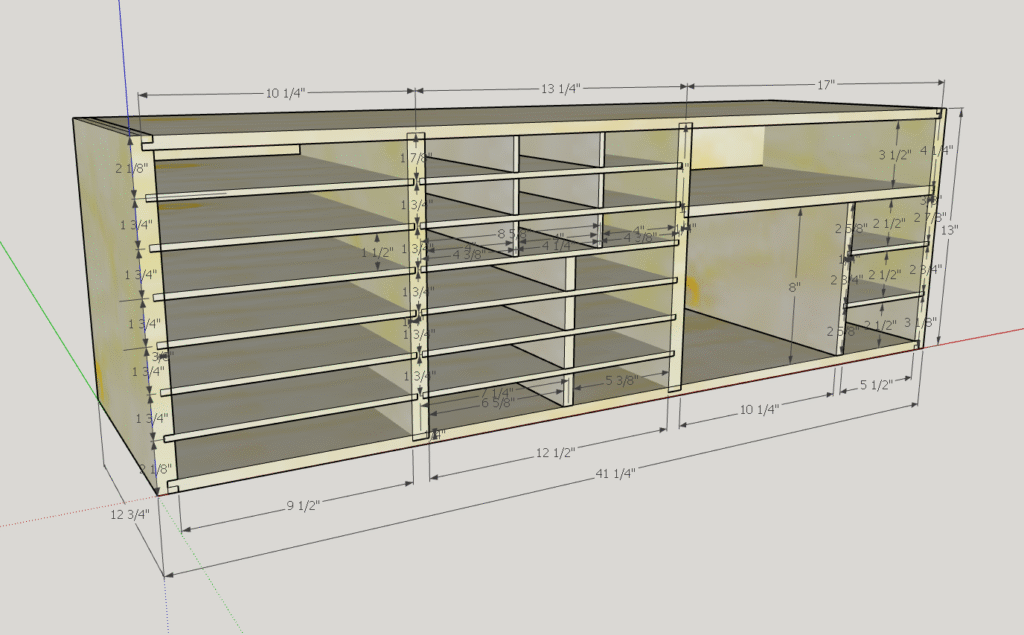

The first task is to create plans in SketchUp.

After creating plans, the Baltic birch ply parts are cut to dimension.

Next, the joinery features are cut in the parts on the table saw and the router table. Locking rabbets are used at the corners of the carcass, and dados are used to secure the fixed and sliding shelves. The shelf dados are cut using specially sized router bits that match the weird thicknesses of plywood. As is my general practice, no fasteners were used.

The main parts forming the carcass are dry fit.

The dry fit looks good.

Finger reliefs are cut in the shelves on the drill press with a forstner bit.

One of the vertical dividers had to be radiused on the oscillating spindle sander to match the finger relief in the shelf above it.

The carcass is glued up in stages.

The fit in the router table looks good.

The cabinet is filled with sandpaper, the palm sander, and sanding blocks. It’s a real pleasure to have all the sanding supplies organized, accessible, and in one place.

Thanks for your interest.